- Tout

- Nom du produit

- Mots-clés

- Modèle de produit

- Résumé du produit

- Description du produit

- Recherche en texte intégral

| État de disponibilité: | |

|---|---|

| Quantité: | |

1. Suivi stable et précis pour 7 000 mm / 23 pieds.

En tête de la plupart des concurrents, la série GR8000 est capable d'effectuer un suivi stable sur une longue longueur de 700 mm / 23 pieds, ce qui est une caractéristique importante pour le traitement de haut niveau, elle est idéale pour la création de grandes enseignes et de modèles.

2. Couper avec précision les petites chaînes de texte.

Il peut couper un cercle d'au moins 0,8 mm et il est facile de déchirer les déchets.

3. Sans électricité statique.

Le problème des interférences électrostatiques de friction lors de la coupe de matériaux fins et mous est résolu sur traceur de découpe GR8000.

4. Compatibilité avec Adobe Illustrator (AI), CorelDraw, AutoCAD et plus encore.

Caractéristiques

Modèle | GR8000-80 | GR8000-140 | GR8000-180 | |

Max. Largeur de coupe (Découpe sans contour) | 690mm | 1290mm | 1630 mm | |

Max. Largeur de coupe (Découpe de contours) | 600mm | 1220mm | 1520mm | |

Max. Largeur du support montable | 840mm | 1440mm | 1780mm | |

Min. Largeur du support montable | 70mm | |||

Max. Vitesse de coupe | 800 mm/s | |||

Max. Force de coupe | 600 gf/5,8 N en 8 étapes | |||

Configuration de la force de coupe | Réglable dans chaque 1gf | |||

Conduire | Servomoteur | |||

Résolution mécanique | 0,0125 mm | |||

Min. Diamètre du cercle | 0,8 mm | |||

Min. Taille des caractères | 1x1mm | |||

Min. Taille du nombre | 3x3mm | |||

IOS | Win10/8/7/XP | |||

Mémoire tampon | 2 Mo | |||

Logiciel | Pilote Windows, SignWork Pro, CAO vers Plot Pro | |||

Écran LCD | Anglais/Chinois | |||

Format de fichier | HP-GL,PLT | |||

Port en standard | USB,RS-232 | |||

Détection des marques d'enregistrement | GARMES | |||

Entrée d'alimentation | 90 V-240 V CA, 50-60 Hz | |||

Consommation d'énergie | 60w | |||

Porte-emporte-pièce/porte-stylo | 1 pour chacun | |||

Diamètres de lame de coupe | 0,9 mm, 1,5 mm, 2,0 mm | |||

Angles de la lame de coupe | 30°,45°,60° | |||

Types de stylo | Stylo à pointe fibre à base d'eau et stylo à bille à base d'huile | |||

Méthode pour réparer le matériau | Rouleaux pousseurs | |||

Plaques à rouleaux pour supports de support | Compris | |||

Panier | Pour option | |||

GW/NO | 42/27kg | 96/62kg | 105/72kg | |

Taille du paquet LWH | 118x40x57cm (0,27CBM) | 171x40x57cm (0,4 CBM) | 220x40x57cm (0,5CBM) | |

1. Suivi stable et précis pour 7 000 mm / 23 pieds.

En tête de la plupart des concurrents, la série GR8000 est capable d'effectuer un suivi stable sur une longue longueur de 700 mm / 23 pieds, ce qui est une caractéristique importante pour le traitement de haut niveau, elle est idéale pour la création de grandes enseignes et de modèles.

2. Couper avec précision les petites chaînes de texte.

Il peut couper un cercle d'au moins 0,8 mm et il est facile de déchirer les déchets.

3. Sans électricité statique.

Le problème des interférences électrostatiques de friction lors de la coupe de matériaux fins et mous est résolu sur traceur de découpe GR8000.

4. Compatibilité avec Adobe Illustrator (AI), CorelDraw, AutoCAD et plus encore.

Caractéristiques

Modèle | GR8000-80 | GR8000-140 | GR8000-180 | |

Max. Largeur de coupe (Découpe sans contour) | 690mm | 1290mm | 1630 mm | |

Max. Largeur de coupe (Découpe de contours) | 600mm | 1220mm | 1520mm | |

Max. Largeur du support montable | 840mm | 1440mm | 1780mm | |

Min. Largeur du support montable | 70mm | |||

Max. Vitesse de coupe | 800 mm/s | |||

Max. Force de coupe | 600 gf/5,8 N en 8 étapes | |||

Configuration de la force de coupe | Réglable dans chaque 1gf | |||

Conduire | Servomoteur | |||

Résolution mécanique | 0,0125 mm | |||

Min. Diamètre du cercle | 0,8 mm | |||

Min. Taille des caractères | 1x1mm | |||

Min. Taille du nombre | 3x3mm | |||

IOS | Win10/8/7/XP | |||

Mémoire tampon | 2 Mo | |||

Logiciel | Pilote Windows, SignWork Pro, CAO vers Plot Pro | |||

Écran LCD | Anglais/Chinois | |||

Format de fichier | HP-GL,PLT | |||

Port en standard | USB,RS-232 | |||

Détection des marques d'enregistrement | GARMES | |||

Entrée d'alimentation | 90 V-240 V CA, 50-60 Hz | |||

Consommation d'énergie | 60w | |||

Porte-emporte-pièce/porte-stylo | 1 pour chacun | |||

Diamètres de lame de coupe | 0,9 mm, 1,5 mm, 2,0 mm | |||

Angles de la lame de coupe | 30°,45°,60° | |||

Types de stylo | Stylo à pointe fibre à base d'eau et stylo à bille à base d'huile | |||

Méthode pour réparer le matériau | Rouleaux pousseurs | |||

Plaques à rouleaux pour supports de support | Compris | |||

Panier | Pour option | |||

GW/NO | 42/27kg | 96/62kg | 105/72kg | |

Taille du paquet LWH | 118x40x57cm (0,27CBM) | 171x40x57cm (0,4 CBM) | 220x40x57cm (0,5CBM) | |

Photos | Description |

Rouleaux de poussée rigides précis. Nos rouleaux poussoirs sont fabriqués à partir de matériaux durs, ils sont capables de fonctionner avec précision pendant longtemps. Les rouleaux poussoirs peuvent être réglés sur deux niveaux de pression : Fort/Faible. La combinaison de rouleaux poussoirs rigides précis, de rouleaux d'alimentation en matériau précis et de rouleaux de support de support de qualité assure un suivi stable du matériau sur longue longueur. | |

Suivi stable et précis pour 7 000 mm / 23 pieds. En tête de la plupart des concurrents, la série GR8000 est capable d'effectuer un suivi stable sur une longue longueur de 700 mm/23 pieds, ce qui est une caractéristique importante pour le traitement de haut niveau, elle est idéale pour la création de grands panneaux et de modèles. | |

Chariot à outils avancé. Le chariot à outils est l’une des pièces les plus importantes de la machine. Reprenant la structure d'une voiture de sport, entraîné par un moteur silencieux à bobine acoustique, le chariot à outils du traceur GR8000 se présente comme étant rapide, plus agile et sans surchauffe pour un fonctionnement non-stop à long terme. | |

Table de découpe par aspiration. Entrées d'air denses et flux d'air puissant pour maintenir le support à plat et fermement contre le dessus de la table afin que le chariot à outils puisse effectuer une découpe/traçage rapide et précis. | |

Servomoteur / Contrôle en boucle fermée. La découpe/le traçage sera arrêté lorsque le chariot à outils est en surcharge. Il s'agit d'une fonction de sécurité importante pour protéger le chariot à outils lorsque le support est coincé. | |

Règle à grille. Il est inévitable que la table de coupe ou la surface du matériau ne soit pas à la même hauteur d'un point à l'autre, nous prenons Grating Ruler, un dispositif optique précis, pour mesurer la distance entre la pointe de la lame et la surface du matériau en temps réel, et la profondeur de coupe est ajusté tous les 0,01 mm par le contrôleur en temps réel en fonction de la valeur des distances mesurées. Par la suite, la lame se déplace de haut en bas à mesure que la surface du matériau monte et descend afin de conserver la même profondeur de coupe à n'importe quelle position de ce parcours d'outil sur toute la taille de travail. En bref, la profondeur de coupe est constante ; vous ne verrez pas de nuances différentes. | |

Élimination électrostatique. L'élimination complète des interférences statiques est particulièrement importante pour les installateurs PPF. Le traceur de découpe de la série GR8000 élimine avec succès les interférences statiques après avoir été testé toute l'année dans différentes conditions météorologiques. | |

Coupez les petits textes. Le coupe-vinyle de la série GR8000 est connu pour sa découpe de haute précision, il est capable de couper de petites chaînes de texte, telles que des cercles de Φ0,8 mm, des caractères de 1 x 1 mm et des chiffres de 3 x 3 mm, et il est facile d'arracher les chutes. | |

Composants de qualité. Pour des performances exceptionnelles et un fonctionnement fiable à long terme, nous utilisons uniquement des composants de marque de classe mondiale tels que la courroie BANDO, le roulement MINEBEA, etc. | |

Qualité de bord propre et lisse. La règle de râpage et la gestion correspondante de la force de coupe offrent une qualité de bord propre et lisse, même pour les travaux les plus complexes. La série GR8000 est capable de couper de petites chaînes de texte et il est facile de retirer les déchets, ce qui réduit considérablement la charge de travail des utilisateurs. | |

Réalisation d'une compensation de pointe de lame par puce. Notre système effectue une compensation de la pointe de la lame par le matériel (carte principale) au lieu du logiciel, le coupeur fonctionne avec une haute précision constante quel que soit le type de logiciel CAO/FAO utilisé. | |

Numérisation du code-barres en mode hors connexion. Un simple clic pour repérer le travail de découpe parmi ceux enregistrés dans la mémoire USB en scannant le code-barres imprimé sur le support, sans nécessiter de connexion au PC. Cette fonction est particulièrement utile pour augmenter la productivité lorsque de nombreux fichiers sont stockés dans la mémoire USB. | |

Détection avancée des marques de repérage. Un clic pour ajouter des marques de repérage et générer le(s) contour(s) du ou des objets. Un clic pour lire les repères et effectuer la découpe du contour. Pour adapter au mieux le(s) chemin(s) et contour(s) de coupe, un réglage précis avec le clavier ou le logiciel est disponible. Si le matériau est placé de travers (≤15°), le coupeur est toujours capable de fonctionner correctement, cette fonctionnalité permet de gagner du temps. | |

Force de coupe en 8 étapess. Dans notre logiciel CADtoPlotPro, l'utilisateur est autorisé à mettre différentes couleurs pour différents chemins de coupe et à définir la séquence de traitement comme séquence de couleurs, et différents chemins sont traités par différentes étapes de force de coupe. | |

Msolution multicouche. Pour les supports comportant plusieurs couches, une force de coupe différente est appliquée pour différentes couches. | |

Accélération : 4000 mm/s²/Max. Vitesse : 800 mm/s. Algorithme avancé du contrôleur de mouvement, trajectoires d'outils optimisées, servomoteur sur X, Y, moteur à bobine mobile sur l'axe Z et système d'entraînement de précision de qualité, tous ces éléments permettent à la machine de se déplacer plus rapidement et de traiter avec plus d'efficacité. | |

Algorithme avancé. Un algorithme avancé et un matériel de qualité permettent une élimination évidente des coins déformés, arrondis ou relevés. | |

Pas besoin de SURCOUPE. Sur chaque chemin de coupe, le point de départ et le point final coïncident avec précision, sans nécessiter de SURCOUPE. | |

Demi-coupe / Coupe par perforation. Demi-découpe / Découpe par perforation sont disponibles, à chaque fois vous pouvez réaliser soit l'une soit les deux. | |

Découpe en pointillés. La découpe en lignes pointillées est applicable aux supports à 2 couches généralement ainsi qu'aux types de papier. | |

Un clic pour installer le pilote d'impression. Un clic pour installer le pilote d'impression et l'impression avec USB, envoyer un travail de découpe à partir de n'importe quel logiciel de CAO doté d'une fonction d'imprimante. Notre pilote d'impression fonctionne avec Windows 32/64 bits. | |

Sortie directe DXF. Inutile d'effectuer une conversion de format, le GR8000 est directement compatible avec le fichier .DXF. | |

Un clic pour effacer l'historique. Bouton de suppression en un clic pour le document en cours d'impression. Transférez des fichiers de travail par mémoire USB et prenez en charge les opérations répétées. | |

Calibrage de pointe. Une technologie de pointe de l'industrie est appliquée pour calibrer la perpendiculaire entre les différents axes et le parallélisme entre le portique et la table de découpe. | |

Compatible avec AutoCAD, AI, Coreldraw et Flexisign. Leader du même secteur, nous créons nous-mêmes des logiciels, nous sommes en mesure d'adapter notre système à la dernière version des logiciels de CAO/FAO populaires, tels qu'AutoCAD, Adobe Illustrator, Coreldraw et Flexisign et plus encore. | |

Protocole de poignée de main. Nous fournissons un kit de développement logiciel/SDK adapté au logiciel du client, ce qui approfondit la coopération entre les clients Gunner et Professional. | |

Capteur de média(facultatif) Il est appliqué pour mesurer la taille du support, l'opération de découpe/traçage ne sera pas effectuée si la taille du support n'est pas assez grande pour le contenu, et le contrôleur demandera à l'opérateur d'agrandir le support ou de diminuer la taille du contenu. Le capteur de média aide grandement à économiser les médias et à augmenter l'efficacité. |

Photos | Description |

Rouleaux de poussée rigides précis. Nos rouleaux poussoirs sont fabriqués à partir de matériaux durs, ils sont capables de fonctionner avec précision pendant longtemps. Les rouleaux poussoirs peuvent être réglés sur deux niveaux de pression : Fort/Faible. La combinaison de rouleaux poussoirs rigides précis, de rouleaux d'alimentation en matériau précis et de rouleaux de support de support de qualité assure un suivi stable du matériau sur longue longueur. | |

Suivi stable et précis pour 7 000 mm / 23 pieds. En tête de la plupart des concurrents, la série GR8000 est capable d'effectuer un suivi stable sur une longue longueur de 700 mm/23 pieds, ce qui est une caractéristique importante pour le traitement de haut niveau, elle est idéale pour la création de grands panneaux et de modèles. | |

Chariot à outils avancé. Le chariot à outils est l’une des pièces les plus importantes de la machine. Reprenant la structure d'une voiture de sport, entraîné par un moteur silencieux à bobine acoustique, le chariot à outils du traceur GR8000 se présente comme étant rapide, plus agile et sans surchauffe pour un fonctionnement non-stop à long terme. | |

Table de découpe par aspiration. Entrées d'air denses et flux d'air puissant pour maintenir le support à plat et fermement contre le dessus de la table afin que le chariot à outils puisse effectuer une découpe/traçage rapide et précis. | |

Servomoteur / Contrôle en boucle fermée. La découpe/le traçage sera arrêté lorsque le chariot à outils est en surcharge. Il s'agit d'une fonction de sécurité importante pour protéger le chariot à outils lorsque le support est coincé. | |

Règle à grille. Il est inévitable que la table de coupe ou la surface du matériau ne soit pas à la même hauteur d'un point à l'autre, nous prenons Grating Ruler, un dispositif optique précis, pour mesurer la distance entre la pointe de la lame et la surface du matériau en temps réel, et la profondeur de coupe est ajusté tous les 0,01 mm par le contrôleur en temps réel en fonction de la valeur des distances mesurées. Par la suite, la lame se déplace de haut en bas à mesure que la surface du matériau monte et descend afin de conserver la même profondeur de coupe à n'importe quelle position de ce parcours d'outil sur toute la taille de travail. En bref, la profondeur de coupe est constante ; vous ne verrez pas de nuances différentes. | |

Élimination électrostatique. L'élimination complète des interférences statiques est particulièrement importante pour les installateurs PPF. Le traceur de découpe de la série GR8000 élimine avec succès les interférences statiques après avoir été testé toute l'année dans différentes conditions météorologiques. | |

Coupez les petits textes. Le coupe-vinyle de la série GR8000 est connu pour sa découpe de haute précision, il est capable de couper de petites chaînes de texte, telles que des cercles de Φ0,8 mm, des caractères de 1 x 1 mm et des chiffres de 3 x 3 mm, et il est facile d'arracher les chutes. | |

Composants de qualité. Pour des performances exceptionnelles et un fonctionnement fiable à long terme, nous utilisons uniquement des composants de marque de classe mondiale tels que la courroie BANDO, le roulement MINEBEA, etc. | |

Qualité de bord propre et lisse. La règle de râpage et la gestion correspondante de la force de coupe offrent une qualité de bord propre et lisse, même pour les travaux les plus complexes. La série GR8000 est capable de couper de petites chaînes de texte et il est facile de retirer les déchets, ce qui réduit considérablement la charge de travail des utilisateurs. | |

Réalisation d'une compensation de pointe de lame par puce. Notre système effectue une compensation de la pointe de la lame par le matériel (carte principale) au lieu du logiciel, le coupeur fonctionne avec une haute précision constante quel que soit le type de logiciel CAO/FAO utilisé. | |

Numérisation du code-barres en mode hors connexion. Un simple clic pour repérer le travail de découpe parmi ceux enregistrés dans la mémoire USB en scannant le code-barres imprimé sur le support, sans nécessiter de connexion au PC. Cette fonction est particulièrement utile pour augmenter la productivité lorsque de nombreux fichiers sont stockés dans la mémoire USB. | |

Détection avancée des marques de repérage. Un clic pour ajouter des marques de repérage et générer le(s) contour(s) du ou des objets. Un clic pour lire les repères et effectuer la découpe du contour. Pour adapter au mieux le(s) chemin(s) et contour(s) de coupe, un réglage précis avec le clavier ou le logiciel est disponible. Si le matériau est placé de travers (≤15°), le coupeur est toujours capable de fonctionner correctement, cette fonctionnalité permet de gagner du temps. | |

Force de coupe en 8 étapess. Dans notre logiciel CADtoPlotPro, l'utilisateur est autorisé à mettre différentes couleurs pour différents chemins de coupe et à définir la séquence de traitement comme séquence de couleurs, et différents chemins sont traités par différentes étapes de force de coupe. | |

Msolution multicouche. Pour les supports comportant plusieurs couches, une force de coupe différente est appliquée pour différentes couches. | |

Accélération : 4000 mm/s²/Max. Vitesse : 800 mm/s. Algorithme avancé du contrôleur de mouvement, trajectoires d'outils optimisées, servomoteur sur X, Y, moteur à bobine mobile sur l'axe Z et système d'entraînement de précision de qualité, tous ces éléments permettent à la machine de se déplacer plus rapidement et de traiter avec plus d'efficacité. | |

Algorithme avancé. Un algorithme avancé et un matériel de qualité permettent une élimination évidente des coins déformés, arrondis ou relevés. | |

Pas besoin de SURCOUPE. Sur chaque chemin de coupe, le point de départ et le point final coïncident avec précision, sans nécessiter de SURCOUPE. | |

Demi-coupe / Coupe par perforation. Demi-découpe / Découpe par perforation sont disponibles, à chaque fois vous pouvez réaliser soit l'une soit les deux. | |

Découpe en pointillés. La découpe en lignes pointillées est applicable aux supports à 2 couches généralement ainsi qu'aux types de papier. | |

Un clic pour installer le pilote d'impression. Un clic pour installer le pilote d'impression et l'impression avec USB, envoyer un travail de découpe à partir de n'importe quel logiciel de CAO doté d'une fonction d'imprimante. Notre pilote d'impression fonctionne avec Windows 32/64 bits. | |

Sortie directe DXF. Inutile d'effectuer une conversion de format, le GR8000 est directement compatible avec le fichier .DXF. | |

Un clic pour effacer l'historique. Bouton de suppression en un clic pour le document en cours d'impression. Transférez des fichiers de travail par mémoire USB et prenez en charge les opérations répétées. | |

Calibrage de pointe. Une technologie de pointe de l'industrie est appliquée pour calibrer la perpendiculaire entre les différents axes et le parallélisme entre le portique et la table de découpe. | |

Compatible avec AutoCAD, AI, Coreldraw et Flexisign. Leader du même secteur, nous créons nous-mêmes des logiciels, nous sommes en mesure d'adapter notre système à la dernière version des logiciels de CAO/FAO populaires, tels qu'AutoCAD, Adobe Illustrator, Coreldraw et Flexisign et plus encore. | |

Protocole de poignée de main. Nous fournissons un kit de développement logiciel/SDK adapté au logiciel du client, ce qui approfondit la coopération entre les clients Gunner et Professional. | |

Capteur de média(facultatif) Il est appliqué pour mesurer la taille du support, l'opération de découpe/traçage ne sera pas effectuée si la taille du support n'est pas assez grande pour le contenu, et le contrôleur demandera à l'opérateur d'agrandir le support ou de diminuer la taille du contenu. Le capteur de média aide grandement à économiser les médias et à augmenter l'efficacité. |

| Porte-lame fin Ces composants conçus avec précision se trouvent dans le chariot avancé et contiennent la lame de coupe de votre choix. L'outil est réglable manuellement pour obtenir la quantité souhaitée de « sortie de lame » pour le travail en cours. |

| Outil d'étalonnage Utilisé lors de la configuration, puis périodiquement, pour calibrer la fraise. |

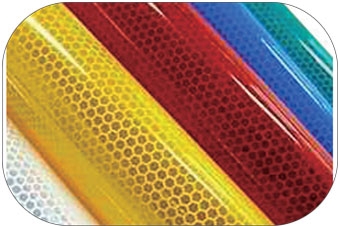

Lames de coupe Différentes lames disponibles pour différentes applications. Angle : 30°/Φ2,0 mm pour des supports plus épais ou des caractères plus petits. Angle : 60°/Φ2,0 mm pour film réfléchissant. Angle : 45°/Φ2,0 mm pour PPF. |

| Porte-lame fin Ces composants conçus avec précision se trouvent dans le chariot avancé et contiennent la lame de coupe de votre choix. L'outil est réglable manuellement pour obtenir la quantité souhaitée de « sortie de lame » pour le travail en cours. |

| Outil d'étalonnage Utilisé lors de la configuration, puis périodiquement, pour calibrer la fraise. |

Lames de coupe Différentes lames disponibles pour différentes applications. Angle : 30°/Φ2,0 mm pour des supports plus épais ou des caractères plus petits. Angle : 60°/Φ2,0 mm pour film réfléchissant. Angle : 45°/Φ2,0 mm pour PPF. |

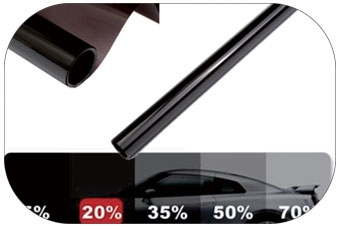

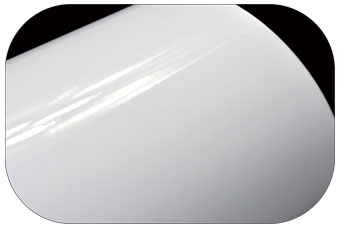

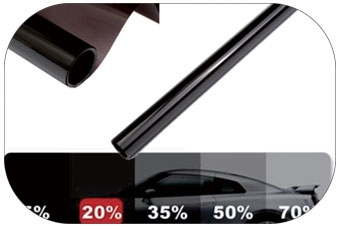

Applications

Divers matériaux autocollants imprimables peuvent être utilisés. Tels que le papier photo, le papier de transfert pour T-shirt, la carte jet d'encre de qualité photo, les autocollants, le papier brillant, les films transparents, etc.

Échantillons de travail

]=]

Applications

Divers matériaux autocollants imprimables peuvent être utilisés. Tels que le papier photo, le papier de transfert pour T-shirt, la carte jet d'encre de qualité photo, les autocollants, le papier brillant, les films transparents, etc.

Échantillons de travail

]=]